World's First Translucent Concrete Facade

Bureau Built Expressions

Innovations in the field of concrete to make it strong, durable, intelligent and beautiful have now reached new heights. The world's first media wall featuring light transmitting concrete has now been built in Aachen, Germany. The 30 meters wide and 4 meters high wall, which includes 136 panels was erected at the RWTH Aachen University campus, is now open to public.

| This visual extravaganza designed by Aachen-based architects Carpus & Partner, establishes a new benchmark in the realm of intelligent and ventilated facades. The world's first media façade featuring LUCEM light transmitting concrete panels was unveiled on 6 December 2012. Concrete panels of size 150 cms x 50 cms containing optical fibres were used to build the wall façade. Each panel fitted with colour-changing technology, with the colours becoming brighter approximately one hour before sunset. The LED-panels are controlled using an internet-based DMX technology system, with each panel containing 3% optical fibres. The light panels are made with red, green and blue chips giving us an option to play with more than 16 million colours. Each individual panel can be controlled independently and thus making the entire façade, a |

|

large display screen.

Calcilith

According to LUCEM, the panels can have various application areas including 'facades, interior walls, claddings and flooring systems. There are currently three different types of LUCEM ®Lichbeton panels, which offer different effects and aesthetics for the user. With the LUCEM® Label panels, light transmitting fibres are arranged individually so that clients can display design logos, images, names, signatures and icons on the panels.

|

LUCEM® panels come in polished, sheen or matte surfaces and can be designed individually. The density of the form in which the fibers are placed creates a compelling visual aesthetic. There are three different types of LUCEM® Lichbeton panels that provide different aesthetics depending on the purpose. With LUCEM® Label panels, light transmitting fibers can be arranged individually so that clients can display design logos, images, names, signatures and icons on the panels.

Another type of the Lichbeton panels include the LUCEM® Line panel. For those who don't want to use LEDs with concrete, a fine-meshed surface gives a more lightweight feeling and allows for silhouetted objects.LUCEM® Starlight panels contain larger fibers that give the effect of brightly lit spots. According to LUCEM, "each panel, |

|

although looks like a solid, organic block of color, only contains 3 percent optical fibers. What's more is that each panel can be controlled independently - meaning that the façade has the potential to be used as a large display screen".

Dimensions

Lucem panels are manufactured in standard size of 1200 x 600mm and can be supplied untrimmed or with machined edges in thicknesses of 15 and 30mm.The panels can be supplied untrimmed as the cutting of panels in any shape can be achieved with a wet cut diamond tipped blade or water jet. The density of the concrete and the flexibility of the optical fibres enable the creation of bespoke shapes with ease.

Properties

Compressive strength: > 70 N/mm2

Density: ca. 2400 kg/m3

Flexural strength: > 5 N/mm2

Building material class: A1/A2, not flammable

UV-stability: durable acc. to ETAG 005 TR 010 severe installation.

Illumination systems

Diffuse natural light and sun light provide the full spectrum of colours shining through the LUCEM panels. Depending on the application, artificial light sources can be used for single colours or even special effects creating fascinatingly exclusive potential for floors, walls, ceilings and independently mounted surfaces.

For an evenly distributed illumination of LUCEM concrete panels, a specially developed lighting source can be provided. This LUCEM Light panel consists of an ultra-flat acrylic panel with two-sided light feeding. This highly efficient and energy saving LED light source is available in white or coloured light, with or without colour alternating modes. The entire installation light zone is 10mm in thickness.

LUCEM Concrete

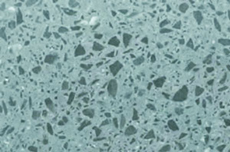

| LUCEM light transmitting concrete is a mixture of fine concrete and optical fibres. These optical fibres are responsible for the lighted surface - the sheen. Concrete is normally a mixture of sand, cement and aggregate and the larger aggregates in the texture of LUCEM light transmitting concrete greatly influence the final appearance. The aggregate granule is the only visual feature if light is not shining through the concrete. Combined with translucent fibres, the structure of the concrete is responsible for the |

|

outer appearance of LUCEM light transmitting concrete.

Concrete consists of a mixture of cement, pigments and sands. The production of LUCEM light transmitting concrete is always based on white cement and therefore can be delivered also in white colour. The colours grey and anthracite are coloured with pigments of ferric iron oxides.

LUCEM's light transmitting concrete is available in three colours which have been tested for long term durability. In addition to the pigmented white cement, the aggregates are mixed with 50 % sand. It should be noted that LUCEM light transmitting concrete is traditional concrete and therefore minor variations and irregularities are to be expected. Air voids also occur in light transmitting concrete and may have a size of 2 mm diameter on the surface.

Reference:

LUCEM Lichtbeton, World Architecture News, ACI RWTH Aachen University Newsletter

BOX INFORMATION-1

Client: BLB NRW / RWTH Aachen

Architect: Carpus+Partner, Aachen

Facade planning: IGF Zimmermann, Mülheim a.d. Ruhr

Year of construction: 2012

Material: LUCEM LINE Anthracite

Format: 150cm x 50cm Special

Concrete surface: 102 sqm

Light system: LUCEM RGB-LIGHTPANEL DMX web based control

Installation: Schendel, Neukirchen-Vluyn

The building owner wanted to have a Facade, which could express the Innovation of this building, by showing from time to time new light scenarios on the surface. During daytime, the Facade looks like a natural stone facade in an elegant Anthracite color, and starting with twilight, the building seems to glow - as a plain glowing area, or with moving lights.

After years of development, the German company LUCEM achieved a level, which allows a serial production of large amount of Light Transmitting Concrete - being automated, simplified and expedited. And the costs have been reduced: the price per square meter is now roughly equivalent to that of stone.