Built Constructions Special Edition

Tech Bytes (Aug 2018)

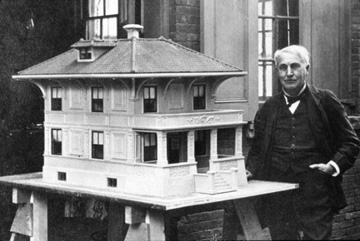

1. Thomas Alva Edison and Concrete

Thomas Edison, famous for inventing many things, including the light bulb, the phonograph, and the motion picture projector, was also passionate about Concrete. This facet of him, the world is not well aware!!

Way back in 1908, Edison filed a patent for the construction of buildings using a single pour of concrete. Since he was way ahead of its time, this proposal was a massive failure. Some of his concrete houses still stand today.

Edison founded the Portland Cement Company in 1899. Despite several innovations, the company went bankrupt. In fact, this company supplied concrete for the construction of Yankee Stadium in 1922, but went bankrupt a few years later.

During this period, Edison also came up with the idea for building homes out of poured concrete. The invention patented in 1917, with the following introduction: “The object of my invention is to construct a building of a cement mixture by a single molding operation, all its parts, including the sides, roofs, partitions, bath tubs, floors, etc., being formed of an integral mass of a cement mixture.”In theory, this would result in a whole new kind of home with various benefits: fireproof, insect-proof, easy to clean, and at a very affordable $1,200 per house. Edison saw this as a potential solution for cities with housing shortages, allowing people to move from slums to cheap new residential areas of poured concrete houses. To help with this, he chose to donate the patented information, completely free of charge, to qualified builders.

Edison had already experimented with reusable formwork molds in 1910, building a garage and a small cottage at his mansion in New Jersey. The reality of doing this on a larger scale, however, was far more complicated. Each house would require a mold consisting of some 2,300 pieces, and a builder would have to buy at least $175,000 in equipment before pouring a single house. And despite Edison’s attempts to describe the homes as elegant and sophisticated, many people still considered them an affordable step-up for slum dwellers rather than a desirable lifestyle choice.

Despite the general lack of interest, the company did build a few concrete houses around New Jersey, some of which still stand. And Edison didn’t let his concrete obsession crumble away. Before the company went bust, he turned to home furnishings. These were to be made using a new lightweight concrete, and would include everything from concrete phonograph cabinets to concrete pianos and concrete bedroom sets (and, for all your afterlife needs, concrete tombstones).

Again, however, it just wasn’t quite what people were looking for. The Edison Portland Cement Company lost millions of dollars, and Edison’s concrete endeavors never quite stuck. Still, he was certainly ahead of his time, predicting current innovations in affordable 3D-printed housing at least 100 years ago.

[Source Credit: www.atlasobscura.com]

2. Sustainability and Structural Steel

“The production of steel from recycled material can use less than one-third the amount of energy needed from starting with raw ore”states Donald W Davies, President, Magnusson Klemencic Associates, Seattle. It’s huge reduction and buildings can take advantage of recycled steel. Steel’s recyclable attributes are only part of the story, as there is a larger storehouse of sustainability benefits provided by structural steel. Today we know that steel is much more than a single-attribute material, and we recognize the many attributes of steel that contribute to sustainable construction in many ways.

Unlike the legacy steel mills of the early 20th century, today’s structural steel mills have highly sophisticated systems to minimize emissions. They are highly automated, environmentally conscious neighbors in the communities where they are located.

Steel does not lose any of its metallurgical properties when recycled. Consequently, the quality and properties of recycled steel are the same as virgin steel.

Iron is a non-depletable resource, as all steel can be recycled, and any increase in demand beyond the available supply of scrap can be met by the earth’s abundant supply of iron, which comprises 35 percent of the earth’s mass.

Structural steel mills recycle all of the water they use through a closed-loop recycling system. Less than 70 gallons of water is consumed per ton of steel produced.

[Source credit:www.continuingeducation.bnpmedia.com]