Seismic Retrofitting Methods for Unreinforced Masonry Brick Walls- A Comparative Study

Introduction

Unreinforced masonry (URM) buildings represent a large portion of the buildings around the world. As we know large numbers of these structures have not been designed for seismic loads and structural walls of these buildings were principally designed to resist gravity loads. Therefore moderate to strong earthquakes can devastate complete cities or villages resulting in massive death toll and cause extensive losses. Hence retrofitting of these structures and improving their strength is significant and vital. Numerous techniques have been developed and applied to improve the seismic behaviour of these structures. In this paper we tried to compare and discuss on seismic retrofitting methods of masonry brick walls, advantages, drawbacks and limitations. Since the majority of human deaths in such building as a result of earthquake are caused because of the out-of-plane corruption of the unreinforced masonry walls, the methods with high potential to improve out-of-plane behaviour was considered.

Retrofitting Methods

There are various methods of retrofitting URM structures in different categories, and some of them are under research and being experimented. Application of these methods to URM structures is expected to increase strength and ductility of the structure. However, sometimes the cost of retrofitting is not reasonable, or advanced technology is needed and therefore isn't suitable for developing countries (that need to retrofit buildings), especially in rural regions. The most suitable methods for retrofitting of URM brick walls are introduced below.

Surface Treatment

Surface treatment is a common method which has largely developed through experience. Since this approach of retrofitting covers the surface of masonry walls, sometimes it is not suitable for historical buildings with architectural value. Recent methods in this category are introduced below.

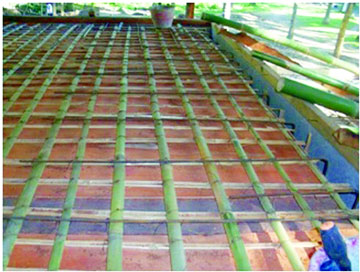

Bamboo-Band Retrofitting Technique

Bamboo-band retrofitting technique is simple enough to be understood and applied by layman without any prior special expertise. Bamboo-band mesh retrofitting techniques enhance the seismic capacity of the adobe masonry building significantly. This retrofitting system consists of vertical and horizontal bamboo used as external reinforcing. At first bamboo band mesh prepare on a square grid in a way that one band crosses over another band in different layers at subsequent crossing points. This process was quite similar to the basket weaving process. Straws place at approximately 200 mm pitch. Holes can be prepared by drilling through the wall. The prepared mesh is then installed on both outside and inside of the wall and wrapped around the comer of the house. The inside and outside meshes are connected by the Polypropylene strings (PP strings) which were passed through the hole.

|

|

|

|

| Figure 1: Preparing Bamboo-Band Mesh and Application |

Experiments have shown that the retrofitted masonry building by this method could withstand over twice larger input energy than what non-retrofitted specimen can do. However, bricks surrounding the bamboo cannot provide proper protection of bamboo meshes. Low cost and no need for special workers are considers as the main advantages of this method.

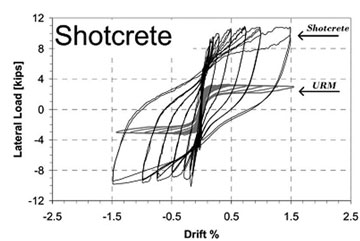

Shotcrete

Shotcrete is a covering method of masonry walls reinforced by mesh of bars, with sprayed concrete. This method of retrofitting is more convenient and less costly than the other retrofitting methods. The thickness of a shotcrete layer can be adapted to the seismic demand. In general, the overlay thickness is at least 60 mm. The shotcrete overlay is typically reinforced with a welded wire fabric at about the minimum steel ratio for crack control. In order to transfer the shear stress across shotcrete-masonry interface, shear dowels (6-13 mm diameter @ 25-120 mm) are fixed using epoxy or cement grout into holes drilled into the masonry wall. This method involves the removal of wythes of bricks and subsequently filling the void with pneumatically applied concrete

|

|

Figure 2: Applying Shotcrete

|

This method of retrofitting consists of:

- Cleaned surface, watered and grinded

- Shear dowels @25-250mm

- Shrinkage control reinforcement

- Wall surface sprayed under 7 Mpa pressure on wall surface.

Experiments showed that retrofitting using Shotcrete is very effective in increasing both strength and ductility of URM walls. Also this method significantly increases the ultimate load of the retrofitted walls. Abrams and Lynch (2001), in a static cyclic test, increased the ultimate load of the retrofitted specimen by a factor of 3. Also the stiffness of the retrofitted specimens at the peak lateral force is approximately 3 times the stiffness of the unreinforced one. Moreover, Shotcrete increases the flexural strength of unreinforced masonry walls and dissipates high-energy due to successive elongation and yield of reinforcement in tension.

Shotcrete typically adds considerable weight to the structure, which results in larger inertia forces during an earthquake and may require foundation adjustments.

FRP

|

|

| Figure 3: Hysteretic curves for a specimen before and after retrofitting using shotcrete (Abrams and Lynch 2001) |

FRP (also fibre -reinforced polymer) is a composite material made of a polymer matrix reinforced with fibres. Fibres are usually glass, carbon, aramid, and also other fibres. This material is lightweight and non-corrosive. Applying FRP method to a URM wall increases both the in-plane and out-of-plane strength of the wall. Schwegler conducted full scale tests on URM walls retrofit with an epoxy bonded carbon FRP. Results showed that both the in-plane and out-of-plane strength were significantly increased as a result of the retrofit. Kolsch showed that the use of a carbon fibre cement matrix composite is very effective in increasing the out-of-plane flexural strength of URM walls. Triantafillou tested several URM walls retrofitted with strips of epoxy-bonded carbon FRP in both in-plane and out-of-plane flexure. Retrofitted walls displayed approximately nine times the capacity of not retrofitted walls in both out-of-plane and in-plane bending. Also under static cyclic loading test, using FRP improved the lateral resistance by a factor of 1.7 to 5.9. However, in some cases debonding occurred at lateral load levels ranging from 50% to 80% of the ultimate load resistance. Some other studies showed that FRP overlays improve the shear resistance of the wall by a factor of 1.3 to 2.9.

|

|

| Figure 4. FRP retrofitting method |

However, due to the coverage of the surface this method is not appropriate for historic structures with architectural value.

Post-Tensioning

Post-tensioning has been used extensively in order to enhance the tensile and flexural capacity of URM walls. For retrofit of URM walls this method is applied by core drilling from the top of the masonry walls and vertically post-tensioning the walls to the foundation. This method involves a compressive force applied to masonry walls. This force counteracts the tensile stresses resulting from lateral loads. Experiments showed that this method can improve the lateral strength of URM walls bay a factor of 2. Al-Manaseer and Neis compared out-of-plane flexural behavior of reinforced masonry wall panels with post-tensioned masonry wall panels. Results showed that the post-tensioned walls displayed a similar level of ductility and an increase in both initial flexural stiffness and strength. While this method is somewhat costly, it has advantages in that it does not alter the appearance of the structure (especially important for historical structures) and that the occupants of the structure need not be disturbed during application.

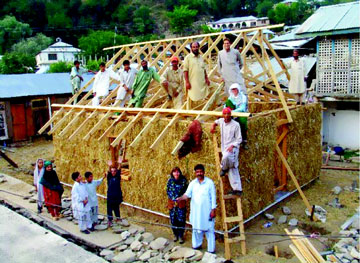

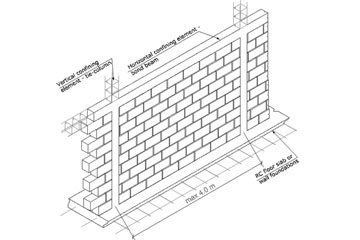

Confinement

In this retrofitting method, tie columns confine the URM wall at corners, intersections, and the border of openings. In some countries like Iran, this method applies to the new masonry construction. However, because of the minor effects of using columns alone for the confinement of walls, it is necessary to apply a horizontal element like a beam to the system. This method improves the ductility and energy dissipation of a masonry structure. The intensity of this improvement depends on the relative rigidity between the masonry and the surrounding frame and material properties.

|

|

Figure 6. Confinement of masonry brick walls

|

Scientists have done many studies about the performance of this method. Karantoni and Faradis by elastic finite element analysis showed that tie columns alone (without tie beams) do not have a significant positive effect on walls behavior. Chuxian et al discovered that confinement prevents disintegration and improves ductility and energy dissipation of URM walls, but has limited effect on the ultimate load resistance. Also Tomazevic and Klemenc proved that before cracking, the confinement effect can be neglected. Zezhen et al find that at ultimate load, the confinement increased the lateral resistance by a factor of 1.2. However, for walls with higher aspect ratio, the confinement increased the lateral resistance by a factor of 1.5. In addition, the confinement improved the lateral deformations and energy dissipation by more than 50%.

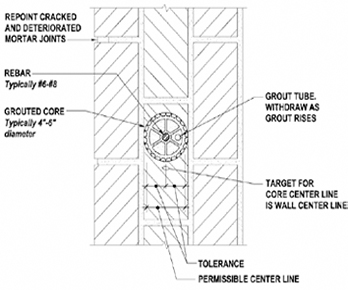

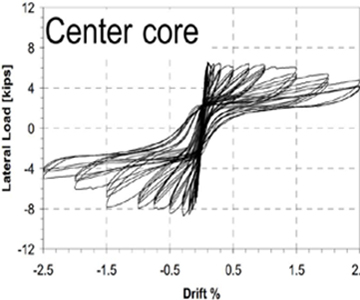

Center Core

Center Core method is advanced method for rehabilitation of masonry buildings. This method is a nondestructive method which could be achieved without evacuation of the buildings. First, vertical holes with given intervals are perforated on the walls to the footing and then reinforcing steel bars are embedded in the holes and cement grout will be injected finally to create bond strength between wall and bars. With existing technology, this core can be drilled precisely through the entire height of two or three-story masonry wall. The drilling is a dry process with the debris removal handled by a vacuum and filter system that keeps the dust to a minimum. After placing the reinforcement in the center of the hole, a filler material is pumped from the top of the wall to the bottom such that the core is filled from the bottom under pressure controlled by the height of the grout. The placement of the grout under pressure provided by the height of the core provides a beneficial migration of the grout into all voids adjacent to the core shaft. This reinforced homogeneous vertical beam provides strength to the wall with a capacity to resist both in-plane and out-of-plane loading. Grout material itself consists of a binder material (e.g. epoxy, cement, and polyester) and a filler material like sand. Abrams and Lynch proved that this technique doubles the resistance of URM wall in a static cyclic test. Although the high lateral displacement achieved during the test, the energy dissipated was limited. Some other experiments showed that ductility and out-of-plain behavior of the retrofitted wall was improved.

|

|

| Figure 7: Plan Detail of Center Core method in Masonry Wall |

The advantage of Center Core system to the owner is the minimal site and interior disturbance and no disfiguring of the internal or external fabric to accomplish safe resistance to future ground shaking. The main disadvantage is this technique tends to create zones with widely varying stiffness and strength properties.

This method of retrofitting consists of:

- A Center Core drilled down to footing (Diameter = 50-125mm)

- Steel rebar inserted with spacers

- Core filled with a mortar, either Epoxy sand, cement sand or Polyester sand. (Polyester mortar is recommended by researchers.)

Injection

|

|

| Figure 8. Hysteretic curves for a specimen after retrofitting using center core (Abrams and Lynch 2001) |

Injection method is an improvement system to retrofit structures. In the case of injection into masonry walls the injection material is injected continuously via low pressure packers, which are in offset arrangement in the form of a grid. In this manner the faulty joints as well as the capillaries, pores and hollow cavities in the bricks are filled in with the injection material. This method of retrofitting consists of:

- Drilling the holes

- Washing of cracks and holes with water. Inject of water (soak of the bricks), from top to bottom of the wall

- Injection of grout with injection pressure of less than 8 to 10 psi.

Since this method does not affect the surface of the wall, it is popular for historical buildings with special architectural features. This technique is very useful for the purposes of improving compressive and shear strength of URM walls by restoring the initial stiffness of it. However, when injection was applied to some parts of the building, it must be proved that any partial increase of structure strength is not dangerous for other parts or the whole wall. For multi wythes masonry walls, injecting grout into empty collar joint enhances composite action between adjacent wythe.

For injection, epoxy resin is used for relatively small cracks (less than 2 mm wide) while, cement-based grout is considered more appropriate for filling of larger cracks, voids, and empty collar joints in multi-wythe masonry walls Schuller et al. used a cement-based grout (100% type III Portland cement ASTM C150 with expansive admixture and w/c ratio of 0.75) to inject 0.08 mm wide cracks. Cement-based grout injection is capable of restore up to about 0.8 of the un-retrofitted masonry compressive strength. In addition, Hamid et al. discovered that cement-based grout injection can increase the interface shear bond of multi-wythe stonewalls by a factor of 25-40. The increment in lateral resistance ranged from 2-4 times the un-retrofitted resistance.

|

METHOD

|

ADVANTAGES

|

DISADVANTAGES

|

|

Bamboo-band

|

Low cost, Available materials, Low technology, Low mass, Structure could withstand twice larger input energy.

|

Affects architecture, Require finishing, Not suitable for historical buildings with architectural value, High disturbance.

|

|

Shotcrete

|

Low cost, Durable and more uniform behavior, Available materials, Improve in-plain strength by a factor of 3.6, Improves out-of-plain stability, Improves energy dissipation.

|

High mass, Require surface treatment, Affect architecture, Require finishing, High disturbance.

|

|

FRP

|

No added mass, Low disturbance, Available materials, Improves shear and flexural strength, Improves in-plain and out-of-plain behavior

|

Affect architecture, Require finishing, High cost.

|

|

Post-tensioning

|

No added mass, Low disturbance, Improves in-plain strength by a factor of 5-6, Improves out-of-plain stability, Suitable for historical buildings with architectural value.

|

High cost, High technology requires, Anchorage problem, Corrosion potential.

|

|

Confinement

|

Prevent disintegration, Improve in-plane deformability, Improves out-of-plain Stability, Improve ductility and energy dissipation.

|

High disturbance, High cost, Require demolition of Wall, Affect architecture

|

|

Center Core

|

No added mass, Low disturbance, Improves in-plain strength by a factor of 2-3, Improves out-of-plain Stability, Improves shear and flexural strength, Suitable for historical buildings with architectural value.

|

High cost, High technology requires, Create zones with varying stiffness

|

|

Injection

|

No added mass, Available materials, Low disturbance, Low cost, Can restore initial stiffness, Improves shear and compressive strength, Improves out-of-plain Stability

|

No significant increase in lateral resistance, Epoxy create zones with varying stiffness and strength

|

Summary and Conclusion

By comparing the retrofitting methods for URM brick walls following results were achieved:

- Applying low cost methods that are not suitably efficient are a financial risk. So it is better to carry out specific study on the economics of retrofitting methods.

- The architectural or historical value of the building must be considered. In such types of structures, surface treatment cannot be used, and it is necessary to study other treatments like injection, Center Core, or base isolation technique.

- Low cost or low technology cannot provide suitable efficiency, however some methods like Bamboo-band retrofitting technique have a relatively appropriate performance.

- As we know the majority of human deaths in buildings as a result of earthquakes are caused because of out of plain corruption of unreinforced masonry walls, so the methods with high potential to improve out of plain behavior must be considered during the selection of the method of retrofitting.

- Because of the low quality of mortar and brick in rural regions, application of post tensioning methods (even for historical buildings) is not recommended.

High mass of URM structures is one of the most important problems that must be considered, and from this view point retrofitting methods with low additional mass are preferable.

References

- Zamani, G. Yamaguchi, K. (2010). A proposal of the most sutable retrofitting methods for URM structures in iran-Anextensive review of recent techniques- . Journal of Habitat Engineering vol 2.No. 2, 105 - 114.

- Elgawady, M., Lestuzzi, p. & Badoux,M. (2004). A review of conventional seismic retrofitting techinques for URM. 13th international brick and block masonry conference. Paper 89.

- Sheppard, P., Tercelj, S. (1980). The effect of repair and strengthening methods for masonry walls. 7th WCEE.vol 6, 255-262.

- FEMA 547. (2006). building type URM. Unreinforced masonry bearing walls. Techinques for seismic rehabilation of existing buildings. Chapter 21. 21-32.

- Smith, A. & Redman, T. (2009). A critical review of retrofitting methods for unreinforced masonry structures. EWB-UK research conference hosted by the Royla academy of engineering.

- Plecnik, J., T. Cousins and E. O'Conner. (1986). Strengthening of Unreinforced Masonry Buildings. Journal of Structural Engineering. American Society of Civil Engineers. Vol. 112, No. 5,1070-1087.

- Elgawady, M. Lestuzzi, P. Badoux, M.(2006 ). Retrofitting of Masonry Walls Using Shotcrete. NZSEE Conference, Paper 45.

- Kahn, L. (1984). Shotcrete retrofit for unreinforced brick masonry, 8th WCEE, 583-590.

- Tumialan, J.G., N. Galati, and A. Nanni. (2002). Field Assessment of URM Walls Strengthened with FRP Laminates. Journal of Structural Engineering, American Society of Civil Engineers.Vol. 129. No. 8.

- Velazquez-Dimas, J.I. and M.R. Ehsani.(2000). Modeling Out-of-Plane Behavior of URM Walls Retrofitted with Fiber Composites. Journal of Composites for Construction. ASCE 4(4).172-181.

- Ganz, H.R. (1993). Strengthening of Masonry Structures with Post-Tensioning. Sixth North American Masonry Conference. 45-655.

- Zezhen, N., Qi, D., Jianyou, C., Runtao, Y. (1984). A study of a seismic strengthening for multi-story brick building by additional R/C columns. 8th WCEE. 591-598.

- Mahdizadeh, A. Borzouie, J. (2011). Perforating the masonry walls in rehabilation of masonry buildings using center core method. 6th International conference on seismology and earthquake engineering. CD-ROM, Paper No. 11461.

Schuller, M., Atkinson, R., Borgsmiller, J.(1994). Injection grouting for repair and retrofit of unreinforced masonry. 10th International brick/block masonry conference. 549-558B.