Selection of Construction Materials

Improving Green rating Factor

Introduction

|

| Low Energy Building using local Materials |

Building contributes almost 40% of CO2 emissions and is a major contributor to the green house gas (GHG) emissions. Different types of construction materials possess a wide variation of embodied energy and emit CO2 at different magnitudes during its life cycle. Selection of appropriate construction materials can considerably cut down CO2 emissions and make our buildings more sustainable and energy efficient. The study is an attempt to address the issues of sustainable construction and how its selection of construction materials can reduce CO2 emissions and play an important role in reducing the impact of climate change directly or indirectly.

Growing global population and prosperity increase the demand for energy and materials. The growth in demand is approximately exponential, meaning that consumption grows at a rate that is proportional to its current value; for most materials it is between 3% and 6% per year. Exponential growth has a number of consequences. One is that consumption doubles every 70/r years, where r is the growth rate in percent per year. It also means that the total amount consumed (the integral of the consumption over time) also doubles in the same time interval.

Most materials are drawn from the minerals of the Earth's land masses and oceans. The resource base from which they are drawn is large, but it is not infinite. Its magnitude is not easy to estimate so that at any point in time only a fraction of it, the reserve, is established as accessible and economically viable. Market forces, when they operate properly, ensure that reserves remain adequate, keep supply in line with demand, and ensure that prices remain stable and fair.

The balance between supply and demand can, however, be disrupted. Depletion of the resource base causes scarcity, driving prices up. Reserves that are localized can become vulnerable to cartel action or cut off by local political unrest. Market disruption can be economically damaging, so foreseeing and anticipating it is necessary if stability is to be maintained. Economic forecasting of this sort is based on the tracking of discovery and production rates of material resources and the identification of their sources, fl aging those for which a single source dominates world markets as vulnerable.

Materials or Products That Minimize Environmental Impacts

Materials and products can cause negative impacts to ecosystems and the environment during all phases of their life cycle. In the materials acquisition phase, mining and harvesting practices can impact habitats and removal of vegetation increases runoff, loss of topsoil, and sedimentation of waterways. Waste piles from mining can leach heavy metals into the soil and ground and surface waters. Emissions and waste from manufacturing can impact air, water, and soil both near and far from the facility. Transport of materials and products between all life-cycle phases uses nonrenewable fuel and releases emissions. Construction and maintenance of materials and products can involve solvents, adhesives, sealers, and finishes that off-gas VOCs or release toxic chemicals to the environment. Dust from unstabilized roads can impact air quality and adjacent vegetation and crops. And disposal of materials and products after their use can fill landfills, impact soil and water around poorly managed landfills, and impact air quality if incinerated.

|

Use Sustainably Harvested or Mined Materials

Some manufacturers take steps to eliminate or mitigate air, water, and soil pollution from their raw material acquisition processes. While mining operations are largely unregulated, some companies make efforts to protect or remediate negative effects from their mining activities. Growth and harvesting of renewable materials can have environmental impacts from fertilizer and pesticide use, impacting soil health and resulting in eutrophication of nearby water bodies. Attention should be paid to farming and harvesting practices of renewable materials.

Use Certified Wood

As it is renewable and has relatively low embodied energy, wood can be considered a green material if it

comes from well-managed forests and is harvested sustainably. Environmentally responsible forest management includes practices that protect the functional integrity and diversity of tree stands, minimize clear cutting, protect old-growth forests, and minimize wasteful harvesting and milling techniques (Forest Stewardship Council [FSC]). The Forest Stewardship Council (FSC) has developed standards for third-party certification of sustainably harvested wood. Certification of lumber should be made by an FSC-certified independent party. Chapter 10 discusses other forest certification organizations.

Use Minimally Processed Materials

Materials and products that are minimally processed (e.g., uncut stone, earth materials, wood, bamboo) often pose fewer ecological impacts. Reduced manufacturing and processing can conserve energy use and potentially harmful emissions and wastes. Minimally processed materials are usually associated with fewer hidden wastes.

Specify Low Embodied Energy Materials

Products that are minimally processed, such as stone and wood, usually have lower embodied energy than highly processed materials such as plastics and metals. Embodied energy is the total energy required to produce and install a material or product during all stages of the life cycle. Evaluating the embodied energy of materials can be a useful baseline for comparing two different materials; however, this type of analysis does not take into account other factors of production such as pollutants and toxins released, resources used, or habitats disturbed. If a product is complex (made from more than one material, such as a steel and wood bench), the embodied energy of the bench would include the energy inputs from both the wood and steel components plus the energy inputs to assemble and finish them.

|

| Carbon Neutral Concrete |

Specify Materials Produced with Energy from Renewable Sources

|

Materials and products produced using renewable energy sources (e.g., solar, wind, hydroelectric, biofuels, geothermal) can have reduced environmental impacts. Combustion of fossil fuels, the primary energy source in a high percentage of manufacturing activities, releases greenhouse gases and air pollutants contributing to global climate change, acid rain, and human respiratory health problems. Any comparison of embodied energy of materials should include an examination of energy sources as a product with relatively high embodied energy may be considered lower impact if it is produced with energy from renewable sources. Aluminum requires around eight times as much energy to produce as a comparable amount of steel, yet its primary energy source is renewable hydroelectric power, whereas the primary fuel energy source of steel is coal. |

| Criteria for Healthy Building Material selection |

Use Local Materials

Transport of building materials, especially heavy or bulky ones, not only requires a tremendous amount of fuel energy, but also contributes to air and water pollution. Using regionally extracted and manufactured materials can help lessen the environmental impact of a material, by reducing environmental impacts of transport. Transportation costs may also be reduced; at the same time the local economy is supported. Availability of regionally manufactured materials depends on the project location. Ideally, heavy materials such as aggregate, concrete, and brick should be procured within 100 miles, medium-weight materials within 500 miles and lightweight materials within 1000 miles of the project site (Living Building Challenge). Distances between raw material extraction locations and manufacturing/processing facilities should be included in these calculations. Researching regionally available materials and products during the schematic design phase can facilitate use of local materials. Creating databases of regional materials and products can save time on future projects within the same region.

Specify Low-polluting Materials

Some raw material extraction, manufacturing, or disposal processes for construction materials produce waste, by-products, and emissions that can contribute harmful pollutants and particulates to air, water, and soil. Some manufacturers minimize pollution from their processes through equipment or process improvement or state-of-the-art pollution controls. Materials with relatively high-polluting processes are metals mining, primary metal production, metal finishing, cement production, and PVC production and disposal.

Specify Low water-polluting Materials

Some materials and products require large amounts of water during processing, manufacturing, or construction. The used water is often contaminated with heavy metals, hazardous chemicals, or particulates and sediments, and is a disposal risk if not treated and remediated. Material manufacturing processes that use large amounts of water or can result in water pollution are metal mining and primary processing, PVC production, stone working, brick making, and lumber processing. Disposal of some materials, such as PVC pipes, can affect groundwater quality. Some manufacturers recycle wastewater back into manufacturing processes. Some employ chemical and heavy metal removal techniques to safely dispose of potential pollutants.

Materials or Products That Pose No or Low Human Health Risks

Low-emitting Materials and Products

Many adhesives, sealers, finishes, and coatings contain volatile organic compounds (VOCs) and other harmful chemical ingredients that can off-gas in use, leading to air pollution, or leach into soil and groundwater in disposal. Construction workers and end users exposed to these chemicals can be adversely affected in many ways. Products containing synthetic chemicals should be carefully examined for harmful effects. Many synthetic chemicals are not biodegradable or easily broken down. The National Research Council estimated that over 65,000 synthetic chemical compounds introduced and in use since 1950 have not been tested on humans (INFORM 1995). Nontoxic, organic, or natural alternative products are increasingly available.

Specify Materials or Products That Avoid Toxic Chemicals or By-products

Materials can contain or emit known toxins during life-cycle phases of manufacture, use, or disposal. Persistent Bioaccumulative Toxins (PBTs), known and suspected carcinogens, teratogens, and products with hazardous chemicals should be avoided. For example, dioxin, a known carcinogen, is released during the manufacture and incineration of polyvinylchloride (PVC) products such as rigid pipe, plastic fencing and railings, drip irrigation tubing, garden hoses, and lawn edging. The EPA's Toxic Release Inventory (TRI) maintains manufacturer's self-reported data on their toxic releases by compound.

Materials or Products That Assist With Sustainable Site Design Strategies

Some site structures may be constructed from materials that are not in and of themselves green, but the way in which they are used contributes to the sustainable function of the site. For instance, use of highly reflective white portland cement concrete, not considered a "green" material because of its relatively high embodied energy, will aid in reducing the urban heat island effect over the life of a pavement, potentially saving energy to cool adjacent buildings. Over the long life of a site, the impacts from manufacture of the material may be minimized with the benefits it can provide for the site's environment.

Products That Promote a Site's Hydrologic Health

Design of sites to respect natural drainage patterns, minimize impermeable surfaces, maximize storm water infiltration, and improve storm water quality can protect the hydrologic health of a site and a region. While polyethylene filter fabric would not be considered a green material, it can go a long way toward ensuring the appropriate function of storm water structures such as bioswales or rain gardens. Green roof products can also promote hydrologic health.

Materials and Products That Sequester Carbon

Lumber, engineered wood products, and many bio based products sequester carbon until they decay; then it is released. New technologies are in development that capture carbon, reducing CO2 from other sources such as carbon-sequestering concrete.

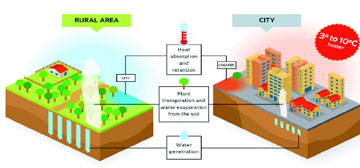

Products That Reduce the Urban Heat Island Effect

Heat island effects result from solar energy retention on constructed surfaces in urban areas, elevating the temperature differential between urban and rural environments. Streets, sidewalks, parking lots, and roofs are the primary contributors to the heat island effect. Use of highly reflective paving materials or open grid pavement structures with vegetation in the cells can reduce the heat island effect. Pervious pavements will cool pavement by allowing air and water to circulate through them.

|

| Urban Heat island Effect |

Products That Reduce Energy Consumption of Site Operation

Products such as solar lights, high-efficiency lights, Energy Star pumps, and irrigation controllers will reduce a site's energy consumption over the life of the site.

Products That Reduce Water Consumption of Site Operation

Products that use water efficiently, such as drip irrigation, irrigation sensors and timers, and rainwater collection barrels, will reduce the site's water consumption.